Assembly Automation

What is assembly automation?

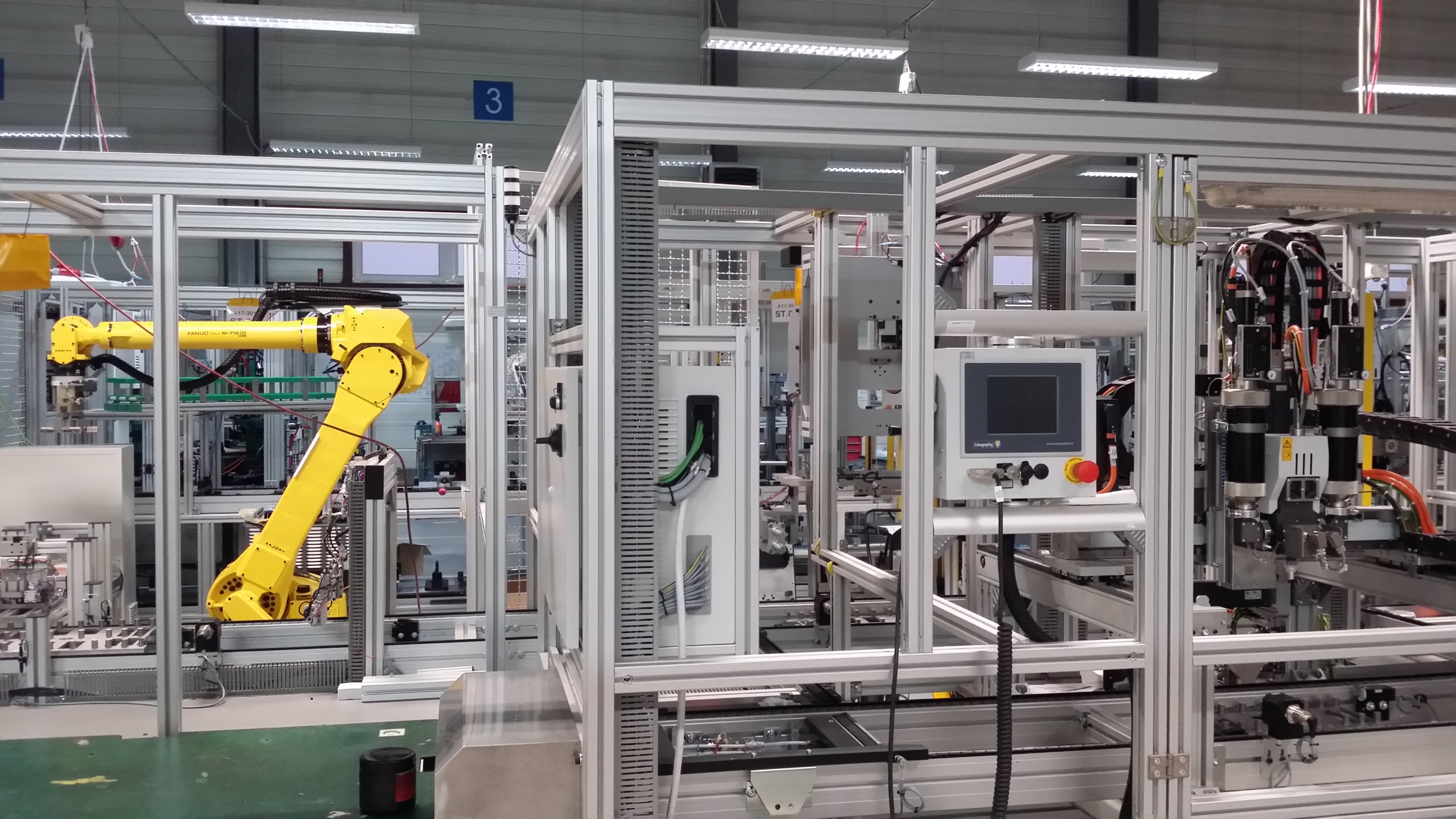

Assembly automation is the strategic integration of advanced technology within assembly processes. Typically this advanced technology includes robotic arms, automated guided vehicles, and sensors to manipulate parts for assembly. Automated robots can be deployed and reconfigured quickly to meet high throughput goals, satisfying increased demand for high-speed and high-quality manufacturing.

Companies across various industries have integrated robotics into their assembly processes for automotive, aerospace, medical, heavy equipment, and consumer products. Further, industries such as consumer electronics, appliances, and medical devices require speed and precision. Automated equipment is ideal for completing repetitive tasks which will be practically not possible using manual labour in some areas.

Automotive assembly solutions

Companies use automated automotive assembly lines for manufacturing components such as fuel systems, motors, gearboxes, and pumps. Robotics and vision are ideal for creating ergonomic and efficient product lines that protect human workers from hazardous conditions while completing assembly quickly.

Aerospace automation assembly solutions

Similar to the automotive industry, the aerospace and defense industries are adopting automation at growing rates. Companies have deployed robotics, vision, and artificial intelligence for welding, assembly, and material handling to increase cycle rates and improve worker safety. These integrations have improved the manufacturing and assembly of all parts of aircraft, ammunition, and weaponry.

Assembly automation improves your bottom line

Assembly robotics boost capacity and quality and lower production costs. Automation solutions can also be flexible, reconfigured, and deployed in other parts of the line. With vision and advanced software, our customers have been able to improve their traceability and quality inspections. Your company can get a return on investment through the following benefits:

- Increased capacity

- Increased quality

- Improved worker safety and ergonomics

- Improved precision and repeatability

One of the most considerable savings is in labor costs. Assembly line robots can take over repetitive and manual tasks, letting your employees focus on the more advanced tasks. Our assembly customers have integrated multiple 6-axis robots and kept areas clear of human workers, saving money by reducing accidents and injuries.

How Onbotics Automation helps assembly processes

Onbotics Automation has the size and experience to provide assembly automation turnkey solutions. Our team of engineers can build proofs of concept and integrate third-party machines, so you have the automation in places you need.

We specialize in integrating assembly, Clinching, material handling & Other special process automation solutions into your production process. Our solutions include feeding systems, riveting and screwdriving, palletizing and depalletizing, pick-and-place solutions, and more.

Technical Capabilities

Whether your parts are manually loaded or fed into our system, we have the know-how to join, press, fasten, rivet, or weld your components together into their final form. Our expertise includes:

| Clinching |

| Sheet metal Forming/Punching |

| Spin Riveting |

| Fastener Insertion in Sheet metal |

| Part feeding |

| Pick & place |

| Press tending |

| Pressing |

| Robotic assembly |

| Robotic palletizing |

| Adhesive & sealant dispensing |

| Adhesives |

| Assembly |

| Bowl feeding |

| Fastening |

| High-speed pick & place |

| Joining |

| Leak testing |

| Linear servo gantry |

| Screwdriving |

| Snap fitting |

| Plastic welding |

| System integration |

| Vision-guided robotics |

| Force /Torque/Effort measurement |

| Process monitoring |

| Vision inspection |

| Auto Gauging system |

| Traceability systems |